AUSTIN SEVEN ENGINE REBUILD

Article kindly

reproduced from the Herefordshire A7 Club.

Part 5 -

Carburettors, manifolds, clutch and fan spindle

Part 1 – The crankcase,

camshaft, oil pump, rear main housing.

Part 2 - The

cylinder block and connecting rods

Part 3 -

Crankshaft & con rods

Part 4 - Main Bearings

Part 6 - Flywheel

Part 7 -

Reassembly

Part 8 -

Attaching the block and cylinder head

Carburettors and

manifolds

I have personal experience of a variety of different

carburettor & manifold combinations on both standard and mildly tuned road-going

Austin Seven engines and my findings are summarised in the following notes.

However, I do not include details of the selection, adjustment and maintenance

of specific carburettors, because there is already a wealth of information

available and indeed whole books written on the subject.

standard and mildly tuned road-going

Austin Seven engines and my findings are summarised in the following notes.

However, I do not include details of the selection, adjustment and maintenance

of specific carburettors, because there is already a wealth of information

available and indeed whole books written on the subject.

In my experience it pays to ensure that manifold

passageways are generally smooth with no sharp steps or corners. It can

sometimes be useful to remember our basic fluid mechanics theory here, that

tells us sudden enlargements are a greater source of friction loss than sudden

contractions of similar proportions. An interesting fact and perhaps somewhat

counter-intuitive.

It is often necessary to remove material to achieve

reasonably smooth passageways and this can be achieved with small grind stones

in a hand-held drill or ‘Dremel’ style flexible drive. It is also important to

remember that gaskets might need trimming to ensure they don’t interfere with

the smooth flow of gas.

I believe the inlet tract is more important than the

exhaust and I am not convinced that a polished finish is necessary in a touring

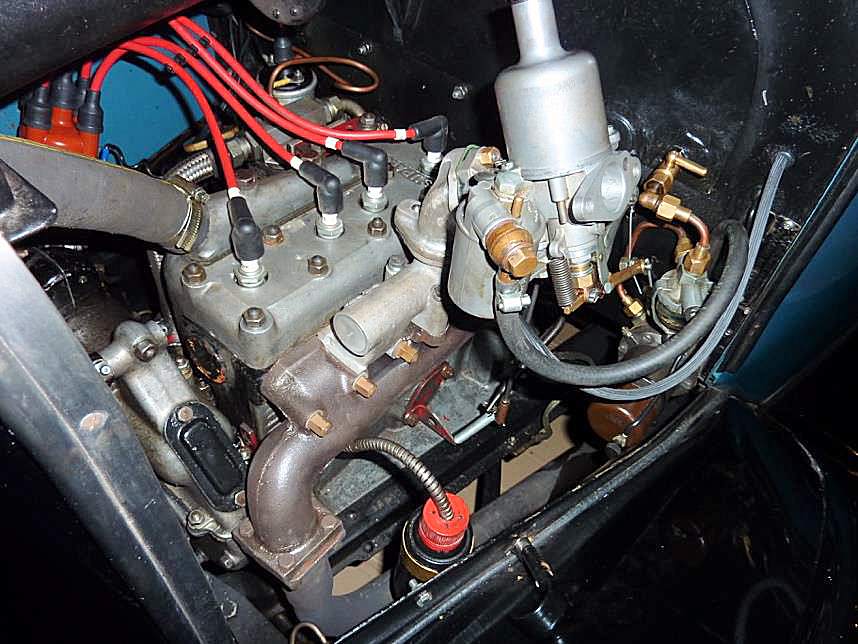

engine. The photo shows a reasonably smooth gas flow path in a current A7 engine

that performs remarkably well.

Many Chummy owners claim surprisingly good

performance with the Updraft 22FZ Zenith carburettor in conjunction with

standard early Austin cast-iron and alloy manifolds. However, I believe this

might have more to do with the light weight of these cars, than efficient

breathing of the engine, because the gas path is unarguably torturous.

My experience is that a side-draft 26VA Zenith

mounted on the Ruby type standard Austin cast iron manifold does offer a slight

increase in power. This is especially noticeable if the narrow throat of the

inlet is opened up from the standard 0.75” Dia, to say 0.95” Dia and the

internal corners nicely rounded.

However, I have a personal preference for SU

Carburettors. They seem to suit Austin Sevens rather well, are often easier to

set-up and being based on a variable jet principle, they enable any slight

blockage to be easily overcome by tugging briefly on the choke. Back in the

Sixties, many A7s sported twin SU carburettors but unless you plan to de-siamese

your inlet ports, it now seems widely accepted that a single instrument will be

more effective and of course a good deal easier to set-up. Whilst on the subject

of jet blockage, I always employ a fuel filter. My preferred type has a fine

brass mesh above a small glass bowl in which I often find small amounts of

debris which are easily removed. One purchase of petrol in rural France on the

2017 Eurotour caused the glass bowl to become completely full of fine grit

particles but happily, nothing reached the float chamber.

So what size and configuration of SU carburettor do I

favour? Well, I have had good results with a 1.00” Dia (measured at the

butterfly) horizontal sidedraft SU fitted to the standard Ruby style

inlet/exhaust manifold; which seemed to give a further improvement in

performance over the 26VA Zenith on the same manifold.

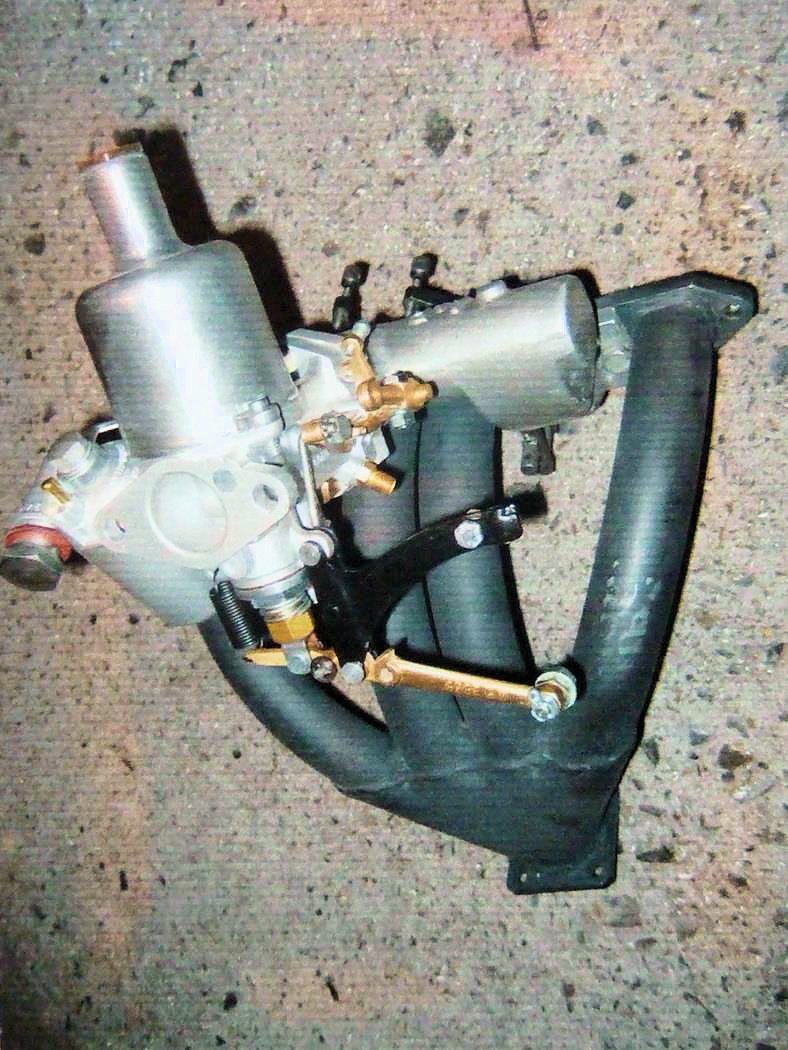

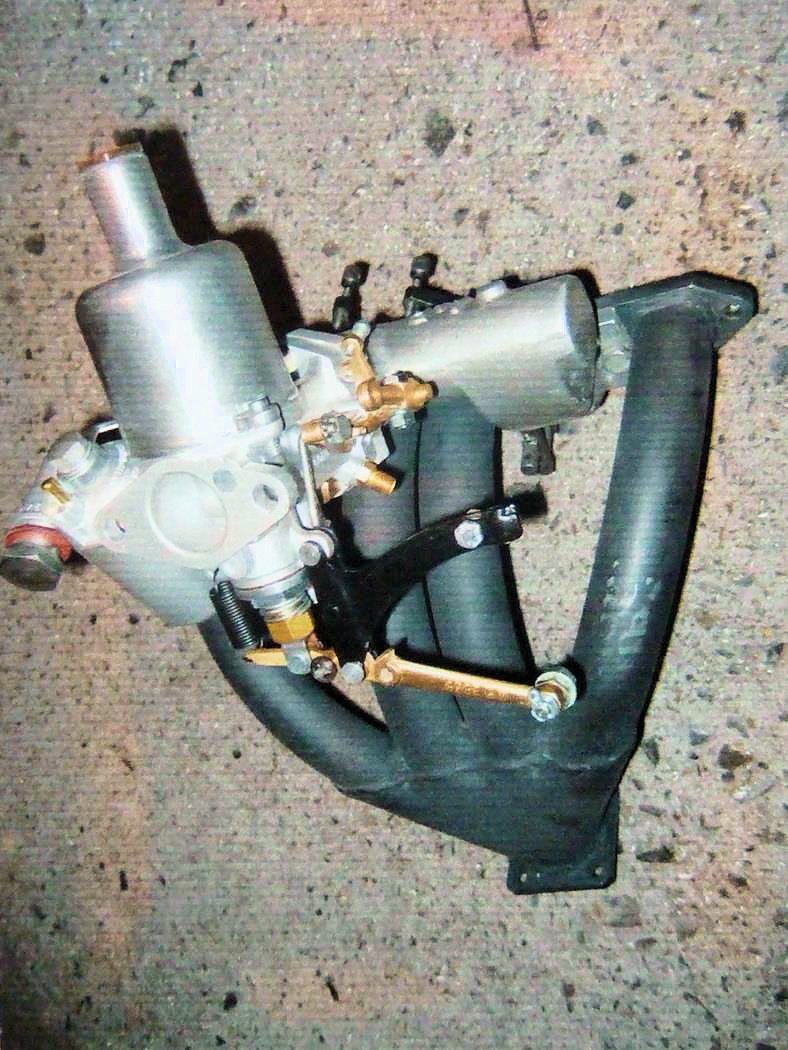

However, a more tasty option is a 30o

1.125” Type H1 SU mounted on an ALR (or similar) alloy inlet manifold with 30o

flange, in conjunction with an ‘bunch of bananas’ steel exhaust manifold such as

the one shown here made by Ian Bancroft.

This combination has worked extremely well for me for

some years but fitting it in-place is not entirely straightforward. Firstly,

there is no room for the centre manifold stud, so this must be blanked-off,

which means the other studs need to be in really good shape. I have previously

mentioned that Sir Herbert’s offerings seem a little frail at ¼” Dia. so I

always make mine 9/32” Dia.

Access to several of the manifold nuts is also

severely restricted with this particular exhaust arrangement, which makes the

length of the studs somewhat critical. Even then, there is insufficient

clearance to accommodate a conventional socket for tightening the nuts. So, I

have resorted to an old box spanner with some material ground-off its outer

surface. Clearly, for structural reasons, it is important not to overdo this

grinding or let it get too hot which would destroy its temper. Happily, old box

spanners are often made of excellent steel and my ground-down version has lasted

many years.

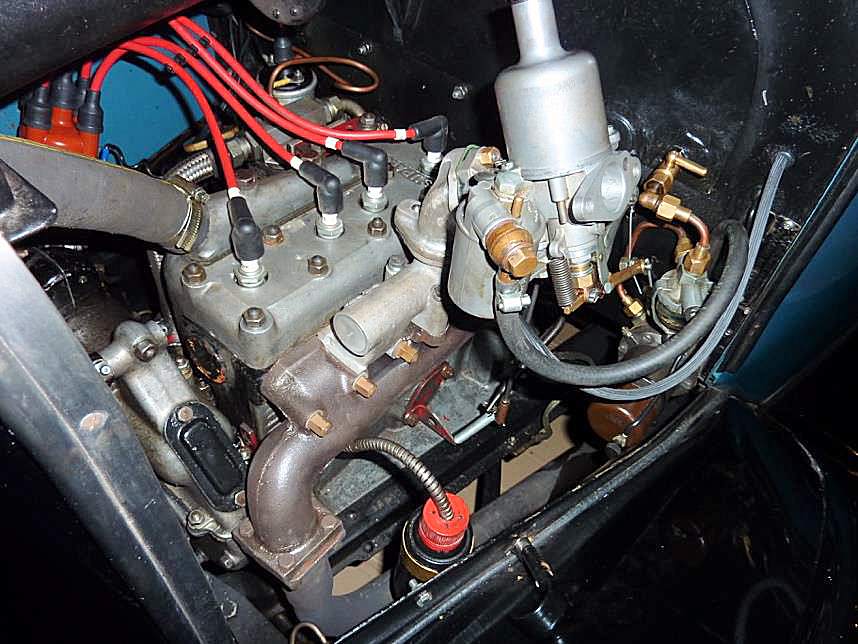

Box saloons (and I guess Rubies) have plenty of room

to accommodate a ‘bunch of bananas’ exhaust manifold but with a ‘Chummy’ it is

more of a squeeze. An easier option in this case, is a swept four branch exhaust

manifold such as that supplied by Pigsty Racing and a fine example can be seen

in the photo on the left of one of our Club cars.

Clearly, with sports exhaust manifolds you have to

make your own arrangements for connecting the exhaust pipe because standard

exhausts will not fit directly. Actually, I have found that they sometimes don’t

fit terribly well even in unmodified cars.

Another interesting option is a Nippy manifold.

Interesting, firstly because it will accommodate a standard exhaust downpipe and

secondly because it seems surprisingly efficient. This efficiency might derive

from a masterpiece of theoretical Longbridge calculation but some argue it is

more likely a happy accident of design. Never mind, it works really well.

Unfortunately, the correct Nippy downdraft Zenith

carburettor (the 30 VE1) has become an endangered species, the last one I saw

for sale about five years ago was severely damaged and still had an asking price

of well over £200. However, several other similar Zeniths make excellent

substitutes and often come-up for sale at reasonable prices. There is also

plenty of available information on suitable choke and jet sizes. 26

For those of us that prefer a variable jet in our

carburettors, it is fairly straightforward to fit a 30 degree aluminium adaptor

to a Nippy manifold as shown in the photo. Standard adapters are available but

the ones I have seen are designed to take a 1.25” HS2 SU, which I believe might

be slightly too big for my road engines.

However, with a little ingenuity, these adapters can

be modified to take a 1.125” H1 SU and I am currently enjoying excellent results

with this configuration. As a point of interest I am currently using a GG needle

which seems about right.

The photo also shows my oil catch tank. The valve

chest cover breather holes are blanked-off and an adapter connects (via a length

of old outer speedo cable) to an old Brasso tin that has a ring of small holes

in its lid. It works surprisingly well.

Since this photo was taken, I have added a short

home-made inlet trumpet, fitted with a coarse gauze to prevent any unwanted

large lumps of grit from entering the engine. It seemed a good idea and there is

just enough room under the bonnet - but it has had no noticeable effect on

performance. At some stage I propose to experiment with some form of air-cleaner

cum silencer but for the moment, I shall continue to enjoy the noisy roar of the

engine, especially noticeable on wide throttle openings.

Clutch

The benefits of even a slightly sporting engine will

obviously be lost if the clutch is in poor shape.

Therefore

unless the linings are obviously fairly new, I invariably replace them when

building an engine. Austin Seven clutch linings are not wildly expensive, they

are dead easy to fit and it gives enormous peace of mind. Similarly, a set of

new clutch springs is also a good idea if yours look a bit compressed compared

to new ones which are typically 1.375” long. Incidentally, although some people

recommend them - I have never felt the need for double clutch springs, even with

fairly pokey engines. Maybe clutch slip is more frequently caused by oil

sneaking into the clutch?

Therefore

unless the linings are obviously fairly new, I invariably replace them when

building an engine. Austin Seven clutch linings are not wildly expensive, they

are dead easy to fit and it gives enormous peace of mind. Similarly, a set of

new clutch springs is also a good idea if yours look a bit compressed compared

to new ones which are typically 1.375” long. Incidentally, although some people

recommend them - I have never felt the need for double clutch springs, even with

fairly pokey engines. Maybe clutch slip is more frequently caused by oil

sneaking into the clutch?

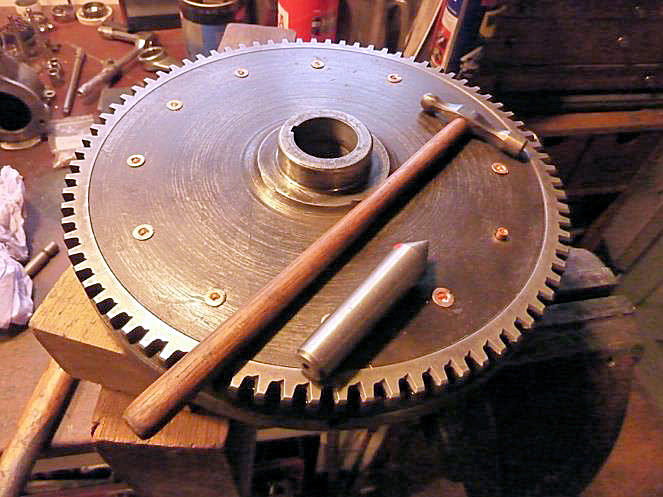

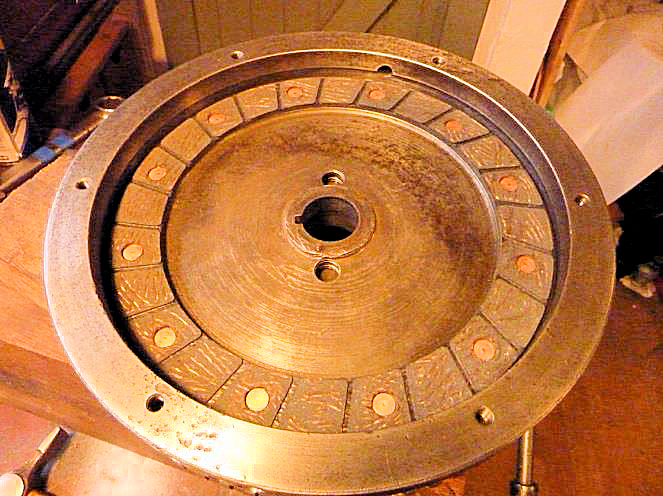

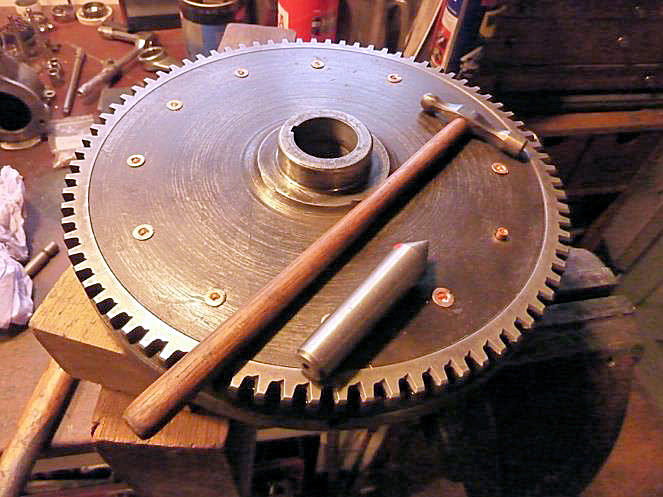

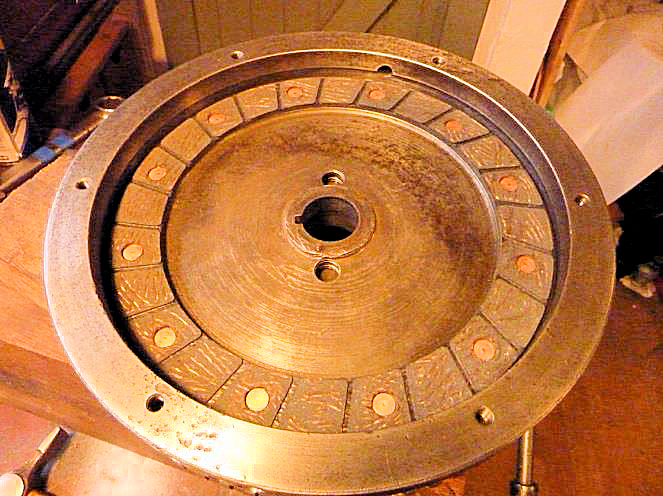

The above photos show a new clutch lining fitted to a

flywheel. I use a mild steel ‘dolly’ of rivet head diameter held in the vice to

support the lining side of the rivet and prop the flywheel in a horizontal

position. I then use a lathe ‘dead centre’ to initially spread the hollow copper

rivet before widening them a little further with the ball-pein end of a small

hammer then finally spread it just enough to hold things firmly together. A

similar approach is followed to re-line the pressure-plate.

A smooth operating clutch also requires the pillars,

clutch levers and pivot pins to be in reason able

condition. New replacement items are available, mostly at reasonable prices

except that a set of three levers will set you back approaching £30. No wonder

it’s common to apply weld to the worn faces and then file them to shape. Play in

the lever pivots can sometimes simply be removed by replacing worn pins with

lengths of 5/16” silver steel. Some books suggest removing wear with oversize

pivot pins and reaming the pillars but this will do your reamer no favours

because the pillars are hardened steel, therefore new items might be a better

option. Woodrow tells us the pivot pins should be a press fit in the levers but

I have found that this is not always the case.

able

condition. New replacement items are available, mostly at reasonable prices

except that a set of three levers will set you back approaching £30. No wonder

it’s common to apply weld to the worn faces and then file them to shape. Play in

the lever pivots can sometimes simply be removed by replacing worn pins with

lengths of 5/16” silver steel. Some books suggest removing wear with oversize

pivot pins and reaming the pillars but this will do your reamer no favours

because the pillars are hardened steel, therefore new items might be a better

option. Woodrow tells us the pivot pins should be a press fit in the levers but

I have found that this is not always the case.

Austin’s recommended practice of bending the levers

for adjustment, really does not appeal to me. I strongly favour the well

established approach of drilling and tapping the clutch cover plate at the pivot

points to take suitable (flat fronted) hex’ drive grub screws. This approach is

described very clearly in Woodrow (A4-26) and enables precise adjustment of the

levers. Incidentally, a tiny amount of low strength thread-lock seems to prevent

these screws from moving in service, whilst still allowing adjustment.

Fan spindle

An interesting article on the (excellent) Cornwall A7

Club Website suggests that many of us might be driving around with our fan-belts too tight. The suggestion

being that a tight belt will try to climb-up the flange rather than sit nicely

on the peak of the convex pulley where it should be. Mine has definitely shown

this tendency for some time and causes one side of the belt to wear rather too

quickly. I therefore experimented with a much slacker belt and noticed an

immediate improvement in its alignment without any noticeable loss of traction

to drive the fan which might otherwise cause overheating.

many of us might be driving around with our fan-belts too tight. The suggestion

being that a tight belt will try to climb-up the flange rather than sit nicely

on the peak of the convex pulley where it should be. Mine has definitely shown

this tendency for some time and causes one side of the belt to wear rather too

quickly. I therefore experimented with a much slacker belt and noticed an

immediate improvement in its alignment without any noticeable loss of traction

to drive the fan which might otherwise cause overheating.

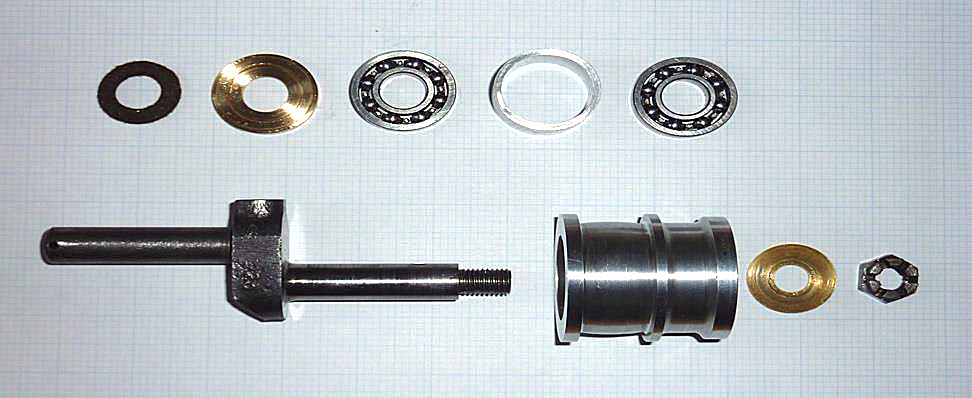

I recently detected some unwanted play in the top

(fan) pulley and decided it was probably time to fit new brass bushes. For some

time the fan belt had been inclined to sit against the pulley flange causing

that edge of the fan belt to fray. I have also noticed that the fan assembly is

inclined to deliver spots of grease in all directions when the engine is

running.

It seemed logical that the worn bushes probably

caused misalignment of the pulley which in-turn led to the worn fan-belt but the

reason for loosing grease was less clear.

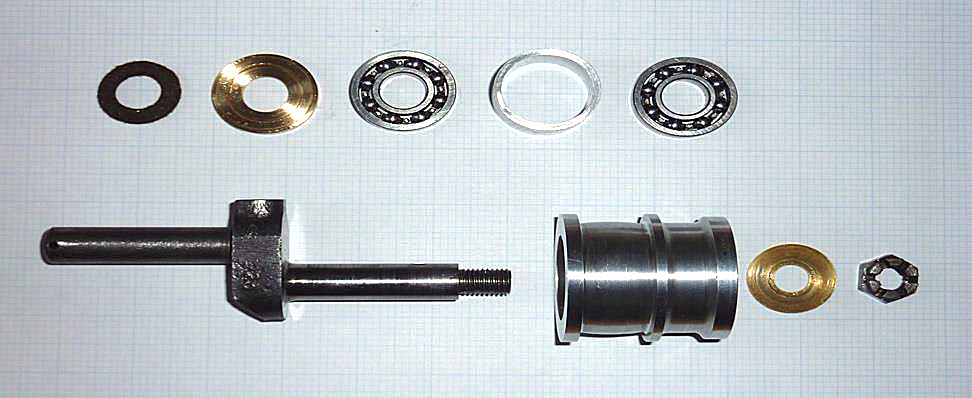

A recent article in the ‘Grey mag’ mentioned the use

of ‘proper’ ball races in a fan pulley and this aroused my interest. A quick

rummage in by box of bearings soon yielded a pair of imperial ball races 1/4”

wide, ½” bore and 1.00” outside diameter. I also found a suitable chunk of

aluminium, and set about designing a new pulley.

Whilst measuring the Austin spindle, I noticed the

drilling (for conveying grease) had been made from the front and left unplugged.

This obviously lets grease reach the back of the fan, which being only a gentle

push fit on the front boss of the pulley – seemed to be a likely source of the

escaping grease. So, I decided to plug the front of this hole but not so far

back as the radial drilling that feeds the bearings. The spindle is hardened on

its outer surface but soft enough in the centre to carefully enlarge the hole to

say 5/32” Dia and tap 2BA with a relatively low percentage engagement to avoid

breaking the tap. Next, after degreasing everything, a 2BA screw was secured in

position with Loctite and cut-off flush at the front end when cured. Finally,

the cross-drilling for the nut split pin was restored.

The new pulley design was very straightforward and

based on positioning the two ball-races as far apart as possible. The Austin

felt seal housing was replicated by a light press fit brass bush to hold

everything together. Finally, the bearings are separated by a simple alloy

spacer.

The bearings were an easy push fit on the spindle and

in the new alloy pulley, so a spot of thread-lock was used to secure everything

in position, obviously taking great care to avoid getting any on the bearing

tracks.

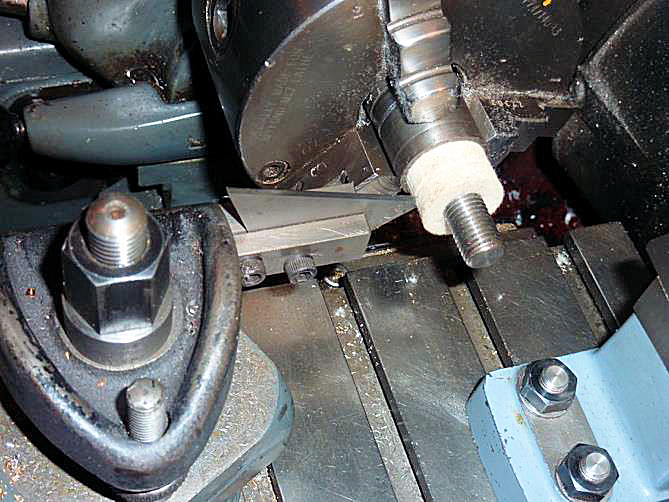

The replacement felt seals that I have encountered

are far too wide at about ½”and need to be cut-down to a thickness of around

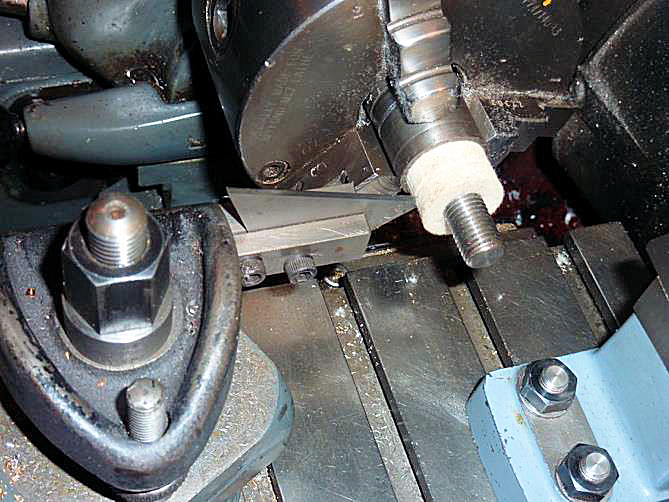

1/4” which means you can keep the remainder as a spare. Cutting can of course be

achieved with the kitchen carving knife but a more accurate approach, is to hold

the felt seal on a 3/8” mandrel in the lathe and cut it with a Stanley knife

blade held in a simple clamp tool as shown in the following photo.

If you run the lathe at top speed and advance the cut

very gently, the seal will only need to be a firm push-fit on the mandrel for it

to remain in place whilst cutting.

Finally, everything was sparingly greased and

adjusted to ensure a light compression of the felt seal. The pull of the fan

exerts a gentle forward axial load when running, that seems to hold the steel

insert against the brass washer at the front sufficiently well to prevent the

loss of grease. This spindle has now done well over a thousand miles, spins very

freely with no play and seems just fine. The relatively loose belt sits nicely

in the centre of the pulleys and the former source of grease spray has been

completely cured. Projects like this probably suggest that I have too much time

on my hands, nevertheless it was an interesting exercise and quite rewarding.

Fuel pump

I personally favour the use of an SU

electric fuel pump and therefore blank-off the aperture for the original

mechanical pump on the near-side of the crankcase. A neat blanking plate can

very quickly be sawn, filed and drilled from an offcut of 1/8” steel and it is

an ideal opportunity to add a bracket to carry the bottom-end of a second

throttle return spring as shown in the photo.

Article kindly reproduced from the Herefordshire A7 Club with

many thanks.

standard and mildly tuned road-going

Austin Seven engines and my findings are summarised in the following notes.

However, I do not include details of the selection, adjustment and maintenance

of specific carburettors, because there is already a wealth of information

available and indeed whole books written on the subject.

standard and mildly tuned road-going

Austin Seven engines and my findings are summarised in the following notes.

However, I do not include details of the selection, adjustment and maintenance

of specific carburettors, because there is already a wealth of information

available and indeed whole books written on the subject.

Therefore

unless the linings are obviously fairly new, I invariably replace them when

building an engine. Austin Seven clutch linings are not wildly expensive, they

are dead easy to fit and it gives enormous peace of mind. Similarly, a set of

new clutch springs is also a good idea if yours look a bit compressed compared

to new ones which are typically 1.375” long. Incidentally, although some people

recommend them - I have never felt the need for double clutch springs, even with

fairly pokey engines. Maybe clutch slip is more frequently caused by oil

sneaking into the clutch?

Therefore

unless the linings are obviously fairly new, I invariably replace them when

building an engine. Austin Seven clutch linings are not wildly expensive, they

are dead easy to fit and it gives enormous peace of mind. Similarly, a set of

new clutch springs is also a good idea if yours look a bit compressed compared

to new ones which are typically 1.375” long. Incidentally, although some people

recommend them - I have never felt the need for double clutch springs, even with

fairly pokey engines. Maybe clutch slip is more frequently caused by oil

sneaking into the clutch?  able

condition. New replacement items are available, mostly at reasonable prices

except that a set of three levers will set you back approaching £30. No wonder

it’s common to apply weld to the worn faces and then file them to shape. Play in

the lever pivots can sometimes simply be removed by replacing worn pins with

lengths of 5/16” silver steel. Some books suggest removing wear with oversize

pivot pins and reaming the pillars but this will do your reamer no favours

because the pillars are hardened steel, therefore new items might be a better

option. Woodrow tells us the pivot pins should be a press fit in the levers but

I have found that this is not always the case.

able

condition. New replacement items are available, mostly at reasonable prices

except that a set of three levers will set you back approaching £30. No wonder

it’s common to apply weld to the worn faces and then file them to shape. Play in

the lever pivots can sometimes simply be removed by replacing worn pins with

lengths of 5/16” silver steel. Some books suggest removing wear with oversize

pivot pins and reaming the pillars but this will do your reamer no favours

because the pillars are hardened steel, therefore new items might be a better

option. Woodrow tells us the pivot pins should be a press fit in the levers but

I have found that this is not always the case.  many of us might be driving around with our fan-belts too tight. The suggestion

being that a tight belt will try to climb-up the flange rather than sit nicely

on the peak of the convex pulley where it should be. Mine has definitely shown

this tendency for some time and causes one side of the belt to wear rather too

quickly. I therefore experimented with a much slacker belt and noticed an

immediate improvement in its alignment without any noticeable loss of traction

to drive the fan which might otherwise cause overheating.

many of us might be driving around with our fan-belts too tight. The suggestion

being that a tight belt will try to climb-up the flange rather than sit nicely

on the peak of the convex pulley where it should be. Mine has definitely shown

this tendency for some time and causes one side of the belt to wear rather too

quickly. I therefore experimented with a much slacker belt and noticed an

immediate improvement in its alignment without any noticeable loss of traction

to drive the fan which might otherwise cause overheating.