|

WINDOW FELTS: When replacing the

window felts

in the runners’ channels, it is quite normal at first for the windows

to bind and not slide smoothly up and down. If this happens, use

French chalk or talcum powder but NEVER use any oil-based product

including oil itself. |

WINDOW WINDING PROBLEMS:

The difficulty in

operating the window of an Austin

Seven may be due to the moulding rail inside the door being slightly bent to

put pressure on the glass. By resetting it the trouble with the window

should be overcome. Also examine the channels on either side of the window

in which the glass rises. These may be binding to make the action of the

window stiff. If they are opened slightly and a trace of thick grease

applied in the bed of each channel the stiffness should be eased. If

attention to these two points fails to correct the trouble, the winding

mechanism may be at fault due to rust resulting from the intrusion of

moisture. Access to this mechanism necessitates removing the winding handle,

which can be detached by levering the small spring catch behind the handle

away from the spindle with which it engages. A loop of wire is sometimes

useful for doing this. The waist-line moulding inside the door and the door

catch are both held by screws which are quite easily removed, and the panel

itself, which is held by screws or panel pins, can be prised away from the

door. The winding mechanism can then be examined and thoroughly greased to

render its action quite free. From the Austin Magazine.

TIGHTENING DOOR HINGES

The Box passenger door just wasn’t shutting properly anymore, often

needing a good slam and, even then, not always catching the latch

fully. We all know that’s most probably due to loose hinges and the

simple solution is to take off the leather door strap, open the door

fully and tighten up the three screws in each hinge. In my case, the

screws just kept turning round without biting into the wooden door

frame so matchsticks and bigger and longer screws were called for.

It seemed to work – at first – until the last job, winding up the

window. Yes, the longer screws in the top hinge had penetrated into the

window channel slightly and blocked the ascending glass. Having a cup of

tea to think it through, I rang Roger Ballard who simply said –

“Rawlplugs, old chap. Simple”. And, of course, they were the solution.

No matchsticks, no slightly sticking out screw heads, just a neat and

very tight solution. Thanks, Roger. Sometimes the obvious solution just

evades us, so I thought I would pass it on.

ADDENDUM From Roge Bateman: Members may be

interested in the inserts, which I have used to great effect many times

in my old cars. Unlike Rawlplugs, they screw in and can’t pull out.

Instead of a wood screw, they take a machine screw and I usually fit a

raised countersunk slotted type for the best appearance. The insert has

a gentle taper on the outside to ensure a snug fit. To use, simply

enlarge the damaged hole using a drill that is approximately equal to

the diameter half way along the root of the outside thread, not the

crest of the threads, and screw the insert in flush with an Allen key.

The centre bore is threaded to accept the machine screw. I have never

needed to Araldite them in and the machine screw can be removed as often

as required. These inserts are available in various sizes on eBay at

about £6 for twenty. Search on ‘Threaded Wood Inserts Type D’.

David Whetton DA7C

|

|

FROST FREE WINDOWS: To keep your

windscreen clear in frosty weather and to help your windscreen wiper in the snow,

lift the offside of the bonnet and, using a wedge or piece of card

between the bonnet and scuttle and close the bonnet again. You

will now have a small gap which will let the hot air from the engine

keep your windscreen warm! |

|

ADDITIONAL BULKHEAD: In an A7 Chummy, install an

additional bulkhead

forward

of the fuel tank to affix any extraneous new fittings such

turn-indicator units, additional fuses etc. (I find screwing these

directly to the existing bulkhead severely worsened my fuel consumption

and gives rise to an awful petrol smell!) Make the new bulkhead of good

quality ply. However, the base of the contact breaker unit needs

to be earthed as wood isn’t the best electrical conductor. |

|

BEZELS:

Do you have a missing or damaged bezel from your petrol gauge or oil

pressure gauge? They are the same size and fitting as Lucas temperature

gauges fitted to 1970's Mini's, albeit a slightly different style.

|

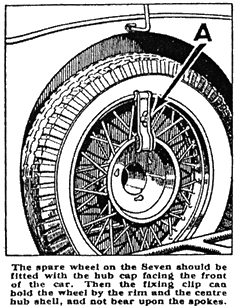

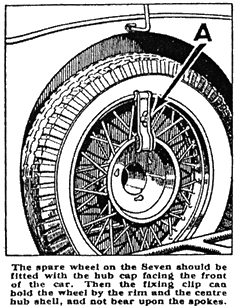

SPARE WHEEL:

It is essential that the

spare wheel be placed in the rear compartment with the brake drum side of the hub exposed; the wheel clamp can then bear

evenly on the rim and the brake drum can be screwed up tight. If the

wheel is replaced facing the wrong way, the clamp bears on one or

perhaps two of the wire wheel spokes and damage is easily caused.

brake drum side of the hub exposed; the wheel clamp can then bear

evenly on the rim and the brake drum can be screwed up tight. If the

wheel is replaced facing the wrong way, the clamp bears on one or

perhaps two of the wire wheel spokes and damage is easily caused.

|

|

LONG LEGS: There may be others large

like me (6ft 6ins and 16 stone) who struggle to get in and out of an A7

comfortably and may benefit from our modification: We have removed the

old battery and box from below the driving seat, relocating it below the

passenger seat. The driving seat can consequently be dropped and pushed

back to rest against the rear seat. The new, low maintenance, 6 volt

battery is available on e-bay at Tanya Batteries.Optima Red-Top RTS 2.1.

Tim Parry DA7C |

GEAR STICK RATTLE:

wrap one turn of electrical

insulation tape around the cup at the base of the gear stick under the

cover plate, so it stuck to itself, then folded the top of the tape over

the cup rim. Although this stopped most of the noise the cover plate

still rattled against the gear stick itself, so again one turn of tape

around the base of the gear sti ck

still allowed the cover plate to slide down but no ck

still allowed the cover plate to slide down but no

more

rattles. Nick Kidd DA7C more

rattles. Nick Kidd DA7C |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

brake drum side of the hub exposed; the wheel clamp can then bear

evenly on the rim and the brake drum can be screwed up tight. If the

wheel is replaced facing the wrong way, the clamp bears on one or

perhaps two of the wire wheel spokes and damage is easily caused.

brake drum side of the hub exposed; the wheel clamp can then bear

evenly on the rim and the brake drum can be screwed up tight. If the

wheel is replaced facing the wrong way, the clamp bears on one or

perhaps two of the wire wheel spokes and damage is easily caused. ck

still allowed the cover plate to slide down but no

ck

still allowed the cover plate to slide down but no

more

rattles. Nick Kidd DA7C

more

rattles. Nick Kidd DA7C