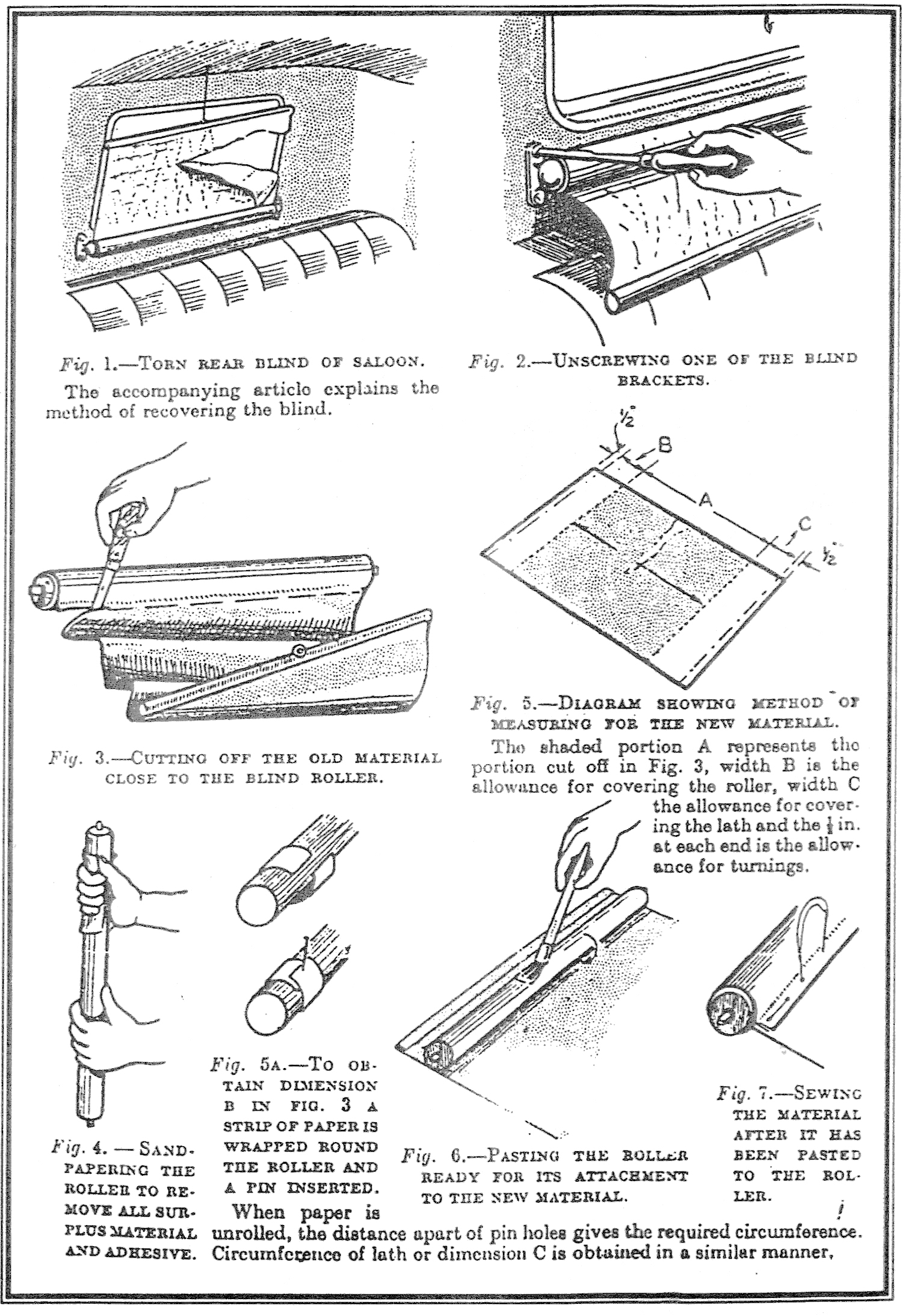

REPAIRS TO REAR BLINDS

The rear blind of the saloon is made of artificial silk,

real silk water proof fabric, or Holland. Artificial silk is the material

chiefly used. It is made in various colours to match the upholstery and is 27

in. wide. The blind (Figs. 1 to 6) is made up on a spring-mounted wooden or

metal roller and rolls up either at the top or bottom of the window. The

last-named type is shown in Fig. 1. The roller is mounted in end brackets and

the leading edge of the blind has a lath inserted in a hem at the centre of

which is fastened a screw eye which takes the operating cord. This extends along

the roof on the off-side to a convenient position in front where the blind may

be controlled from above the driver's seat.

Removing the Blind

The torn blind, shown in Fig. 1, is to be recovered. If the blind does not lift

out of one of its end brackets, then the brackets are unscrewed (Fig. 2), Untie

the knot of the operating cord from the centre screw eye. The blind having been

released from the car, its covering is then cut away with a sharp knife close to

the roller as shown in Fig. 3. The material is probably pasted to its roller so

that any stuff adhering is removed by sand-papering it (Fig. 4). Remove the

screw eye and lath from the end of the blind.

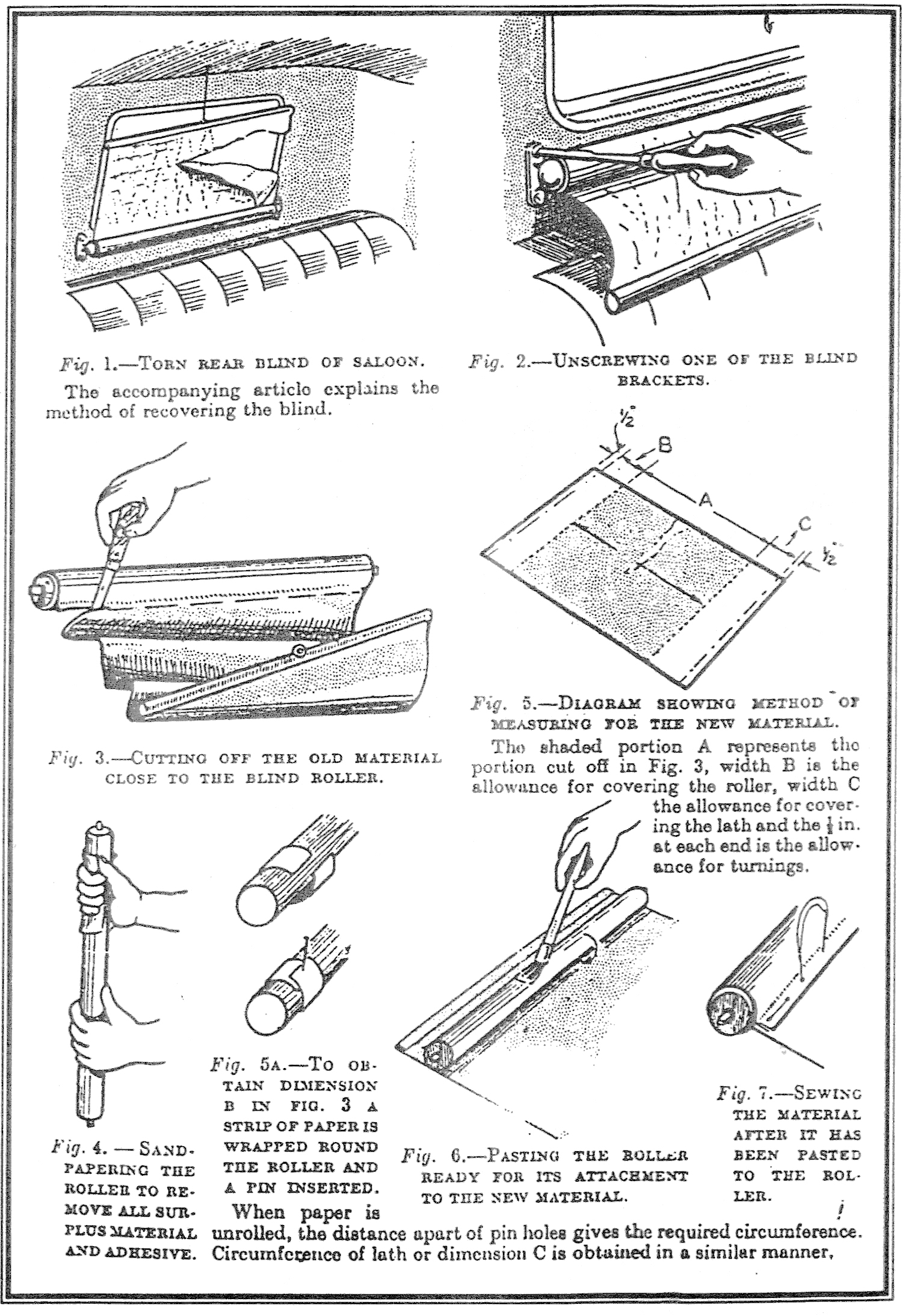

Measuring the Blind Material

A simple method of measuring for the new blind material is illustrated in Fig.

5. Lay the old blind on a piece of new artificial silk. The old blind less the

amount which has encircled the roller is represented by the shaded portion A.

Lengths B and C represent the allowance for covering the roller and lath

respectively while an extra 2 in. each end is allowed for turnings. To ascertain

the length

B cut a strip of paper and wrap it round the roller and then insert a pin

through the overlapping joint. When the paper is unrolled, the distance apart of

the pin holes gives the length required. The circumference of lath C is obtained

in a similar manner.

Ensuring Correct Alignment

In order to ensure the smooth operation of the blind the roller must be

horizontal and the blind material a true rectangle. Also, the edge of the stuff

attached to the roller must be parallel to the longitudinal axis of the roller.

Reinstate the uncovered roller in its brackets at the window and test it with a

spirit level. If any rectification is necessary, plug the screw holes at one end

and adjust the position of the bracket and bore fresh holes. To make sure that

the sides and ends of the new piece of material are parallel fold the stuff

lengthwise and crosswise so that the edges meet. If the roller has no guide line

or lengthwise groove in it, then the roller is laid on a flat surface against a

straight piece of wood which is the same thickness throughout and about half the

diameter of the roller so that a guide line may be marked on the roller.

Attaching Blind to Roller

The blind having been cut to size and the ends turned and sewn, the roller is

laid on the material in the position shown in Fig. 6. Paste or glue is now

applied to the roller and then to the end of the material between it and the

roller. When neatly secured, the material is then sewn with a row of stitching

close to the roller as illustrated in Fig. 7. Sew in the lath in a similar

manner, find the centre, punch a hole with a fine bradawl and insert the screw

eye. Do not turn the bradawl in the usual manner because this will pucker the

material. Insert the screw eye, wind the spring of the roller, reinstate the end

brackets and test the operation of the blind by hand. Before finally inserting

the blind clean the brackets and end fittings of the roller and give a spot or

two of fine lubricating oil and wipe off any surplus. Suitable lubricants which

will not stain the fabric are available.

First appeared in the Essex Newsletter with thanks.