REMOVING THE REAR SPRINGS

I needed to remove the rear road

springs from my Ruby chassis. Woodrow says this is a job that “may be viewed

with some misgiving … because they have a reputation for being reluctant to

move”. How right he was! I made an Ian Moorcraft type spring pin puller (also

available from Willie McKenzie) and it worked faultlessly. With pins removed,

mounting bolts and U-bolts removed, I tried to remove the road springs from the

chassis rails. Following Woodrow’s suggested method, I used “a heavy hammer on

the spring eye to move the spring rearwards”. N o

chance! Each blow rang the spring, which did its job and absorbed the energy.

The springs were stuck in the rails by a mixture of grease and rust that had

hardened. In my industry, this material is called ‘Glit’, a mixture of glue and

...other material. Having hit my thumb, a couple of fingers and the back of my

hand pretty hard, I went indoors to wash off the blood and sweat and have a

coffee. While having coffee, I had a brainwave, I needed to create a dead blow

that would put the energy into the spring mounting.

o

chance! Each blow rang the spring, which did its job and absorbed the energy.

The springs were stuck in the rails by a mixture of grease and rust that had

hardened. In my industry, this material is called ‘Glit’, a mixture of glue and

...other material. Having hit my thumb, a couple of fingers and the back of my

hand pretty hard, I went indoors to wash off the blood and sweat and have a

coffee. While having coffee, I had a brainwave, I needed to create a dead blow

that would put the energy into the spring mounting.

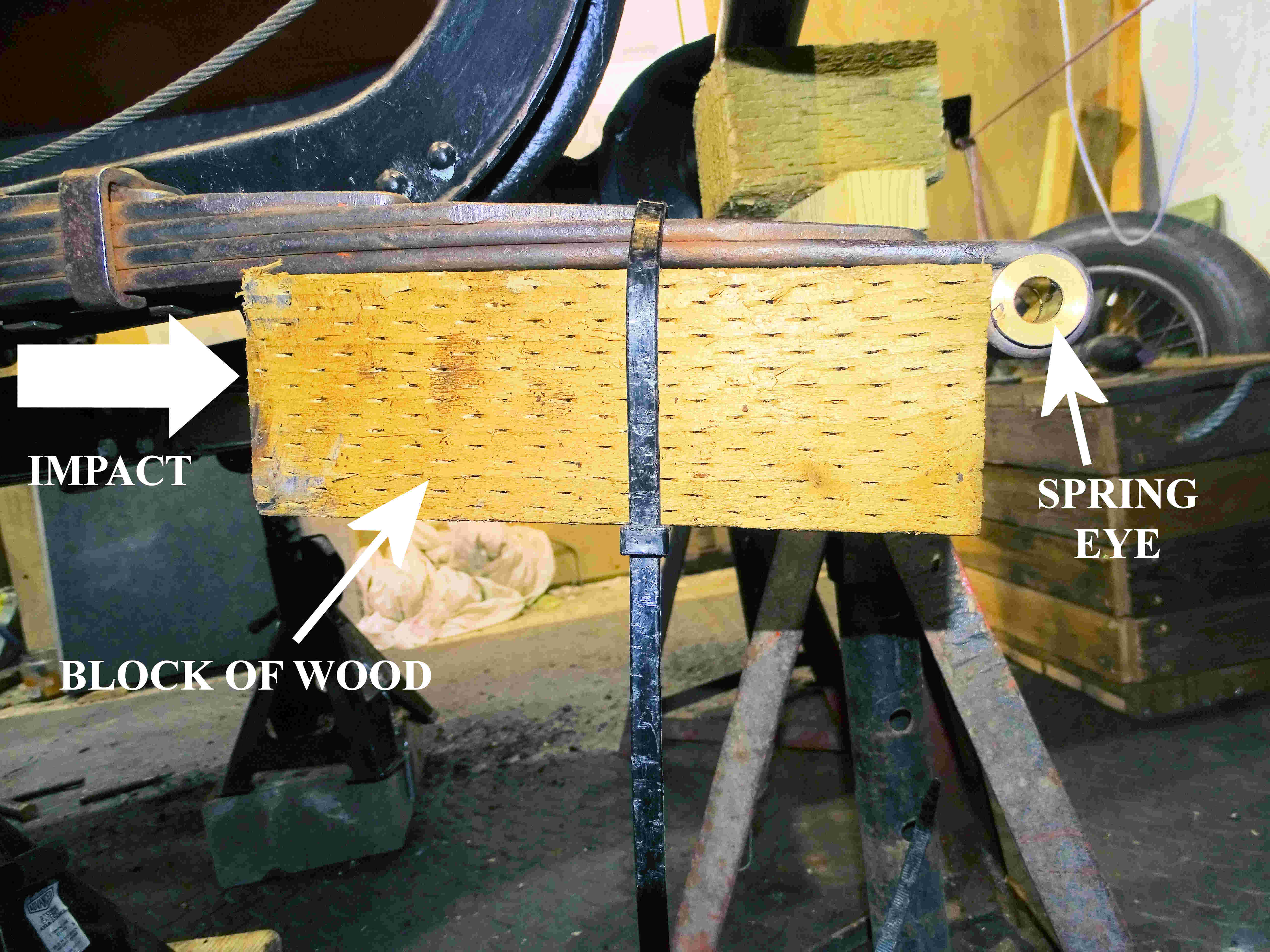

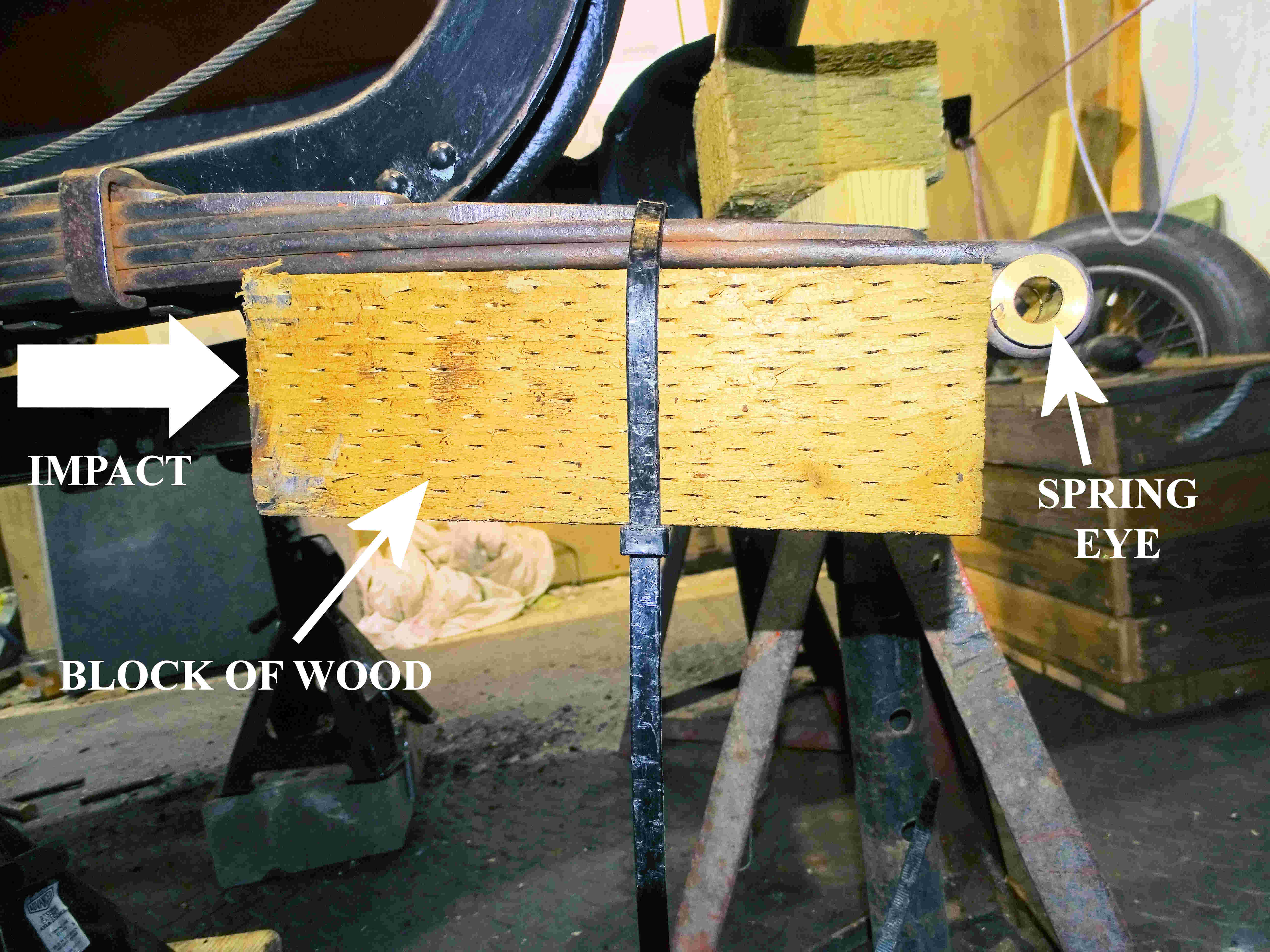

Using a very heavy cable tie, I

lashed

an 8” length of fence post to the spring, butting up against the spring eye.

This moved the point of hammer impact forward of the damper mount and allowed me

a clear swing to hit the wooden block with a sledge hammer. Instead of the

previous ‘dannnnggg’ sound, it made a loud crack with each blow and sure enough,

gradually out came each spring. It just shows the therapeutic effect of good

coffee. Technique credited to ‘Bruce Force and Inga Rance’.

lashed

an 8” length of fence post to the spring, butting up against the spring eye.

This moved the point of hammer impact forward of the damper mount and allowed me

a clear swing to hit the wooden block with a sledge hammer. Instead of the

previous ‘dannnnggg’ sound, it made a loud crack with each blow and sure enough,

gradually out came each spring. It just shows the therapeutic effect of good

coffee. Technique credited to ‘Bruce Force and Inga Rance’.

A couple of words of caution, this

method allows you to apply huge force to the spring. After every few blows,

check that your car or chassis isn’t moving on the axle stands, and don’t get

your fingers in the way as you’ll get more than a pinch or a black finger nail.

Jon Reynolds DA7C

o

chance! Each blow rang the spring, which did its job and absorbed the energy.

The springs were stuck in the rails by a mixture of grease and rust that had

hardened. In my industry, this material is called ‘Glit’, a mixture of glue and

...other material. Having hit my thumb, a couple of fingers and the back of my

hand pretty hard, I went indoors to wash off the blood and sweat and have a

coffee. While having coffee, I had a brainwave, I needed to create a dead blow

that would put the energy into the spring mounting.

o

chance! Each blow rang the spring, which did its job and absorbed the energy.

The springs were stuck in the rails by a mixture of grease and rust that had

hardened. In my industry, this material is called ‘Glit’, a mixture of glue and

...other material. Having hit my thumb, a couple of fingers and the back of my

hand pretty hard, I went indoors to wash off the blood and sweat and have a

coffee. While having coffee, I had a brainwave, I needed to create a dead blow

that would put the energy into the spring mounting.  lashed

an 8” length of fence post to the spring, butting up against the spring eye.

This moved the point of hammer impact forward of the damper mount and allowed me

a clear swing to hit the wooden block with a sledge hammer. Instead of the

previous ‘dannnnggg’ sound, it made a loud crack with each blow and sure enough,

gradually out came each spring. It just shows the therapeutic effect of good

coffee. Technique credited to ‘Bruce Force and Inga Rance’.

lashed

an 8” length of fence post to the spring, butting up against the spring eye.

This moved the point of hammer impact forward of the damper mount and allowed me

a clear swing to hit the wooden block with a sledge hammer. Instead of the

previous ‘dannnnggg’ sound, it made a loud crack with each blow and sure enough,

gradually out came each spring. It just shows the therapeutic effect of good

coffee. Technique credited to ‘Bruce Force and Inga Rance’.