CLUTCH ROLLER BEARING REPAIR

By Steve Fretwell, PWA7C Newsletter with many thanks

.

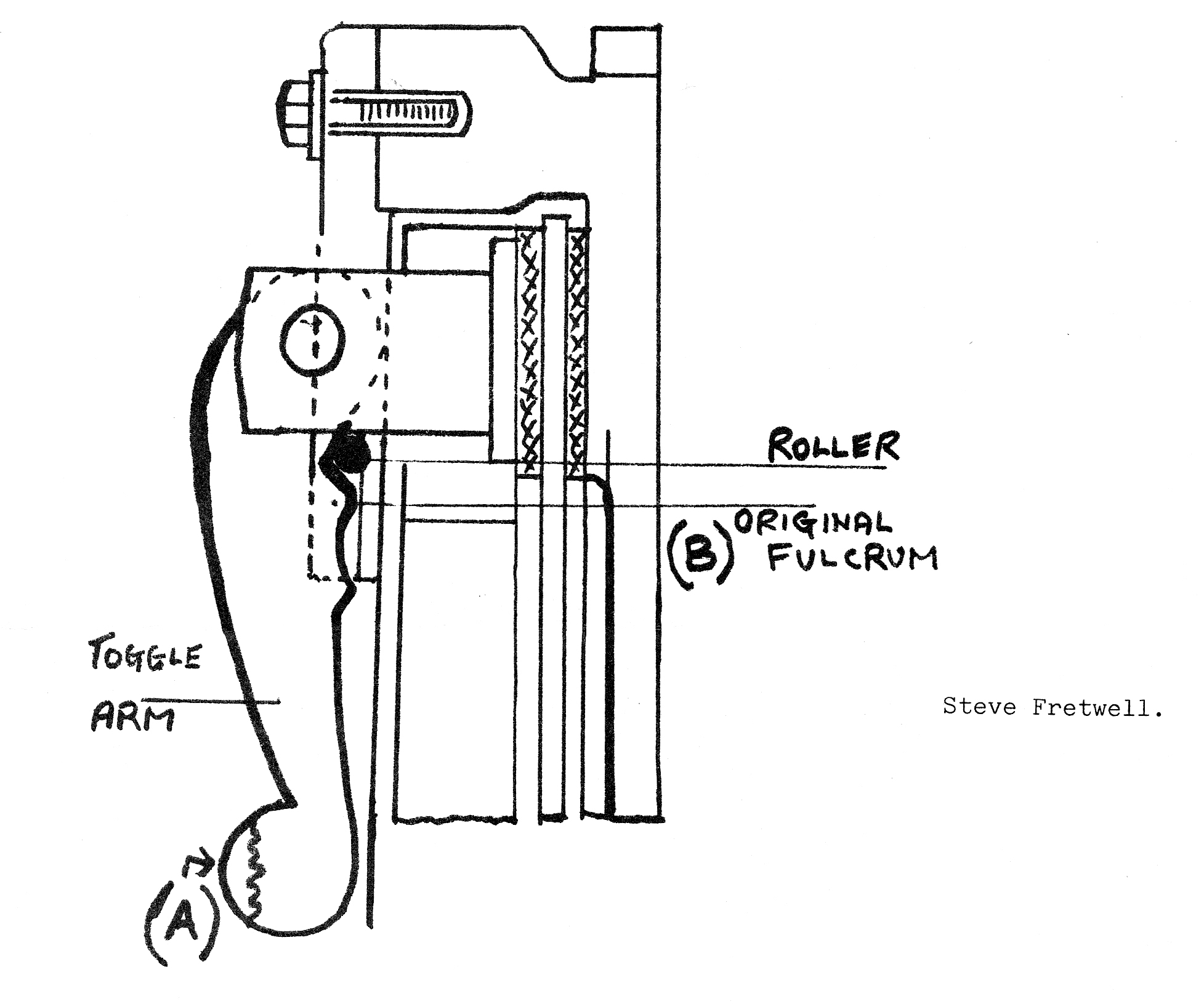

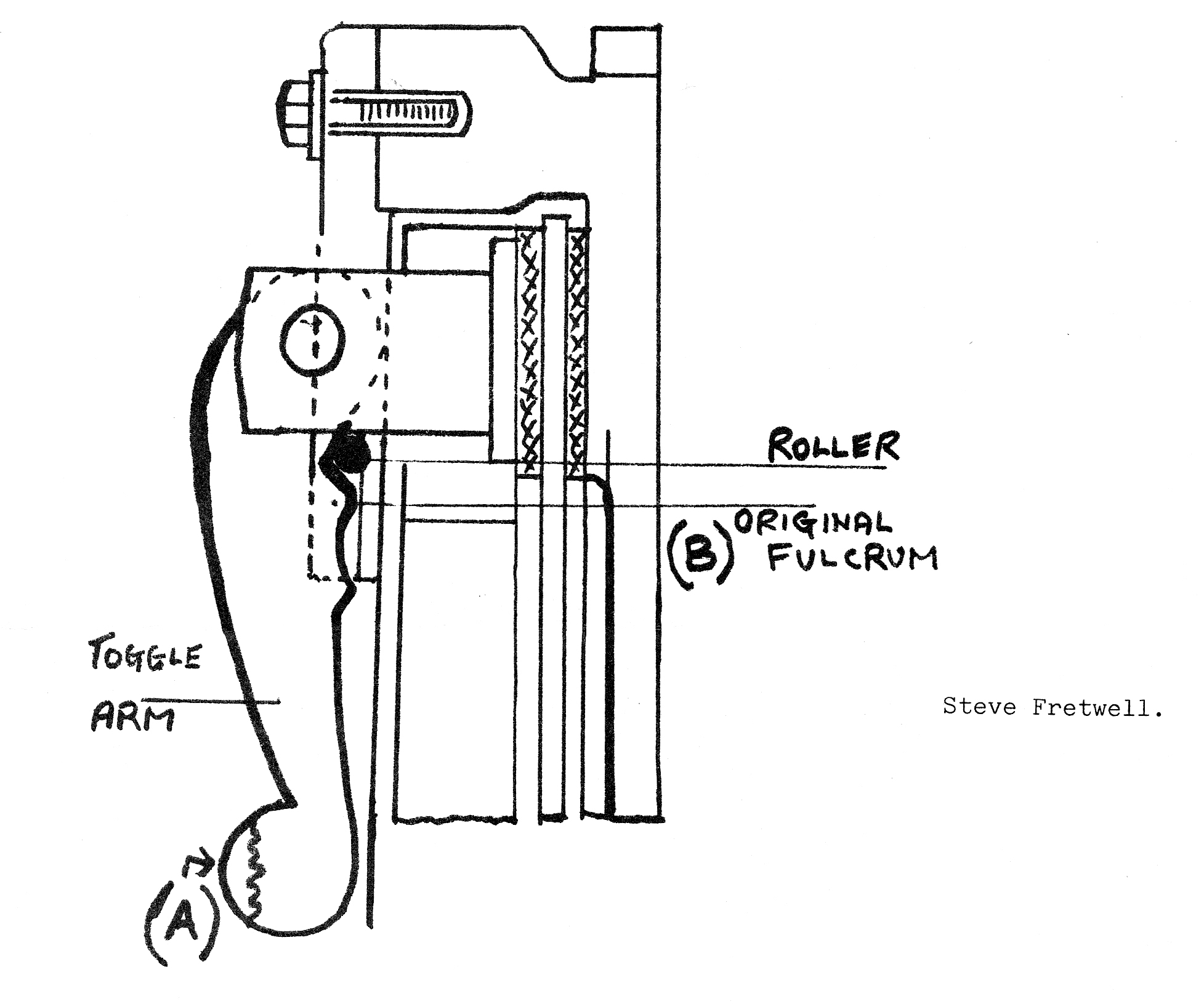

The accompanying sketch illustrates a successful repair I have just carried out

on the clutch of my Austin Seven with three-speed gearbox. The repair also works

on four-speed boxes.

After removing the clutch from my car due to worn out

linings, I noticed that a lot of wear had been caused to the toggle levers

bearing on the cover plate at the bottom of the slots, and on the bearing faces

at the end of the toggle levers (a). Also quite excessive wear was noticed

on the fulcrum points of the toggle arms (b).

To cure the toggle arm ends I successfully built them back up again using very

hard bronze weld. I filed them all back into shape again by setting all three

levers into the vice together, this kept them all about the same shape whilst

the job progressed.

The cover plate at the bottom of the slots was left alone, as the biggest wear was on the lever, and any wear at the bottom of the slots can be taken up by adjustment of the levers when the clutch is reassembled again.

The main wear on the original fulcrum point was cured by fitting a small roller, made from 7/32 in silver steel, into the toggle slot, of such a length that it was a tight fit in the slot. The roller (one for each toggle) was positioned so that it fitted into the hollow in the toggle between the original fulcrum point and the pin eye. The roller not only increases the leverage of the toggle but it makes for a much smoother clutch action.

The toggle arms will have to be reset after the clutch

is fitted back into the flywheel. This is very important. Use care.

Summary of toggle lever settings: -

| 3-SPEED BORG & BECK | 3-SPEED NEWTON BENNETT | 4-SPEED BORG & BECK | 4-SPEED NEWTON BENNETT |

| 5/16 " | 3/8 " | 3/16 " | 1/4 " |