Should petrol appear to be leaking at the edge of the diaphragm, tighten the cover screws alternatively and securely. Sometimes, such leakage may actually come from one of the pipe fittings, causing the fuel to run down the pump and collect round the diaphragm flange.

Fuel pump service is available at all Austin Agents and A.C. Service Stations. Both are stocked with parts and fittings for any repairs and adjustments that may become necessary.

Method of Operation

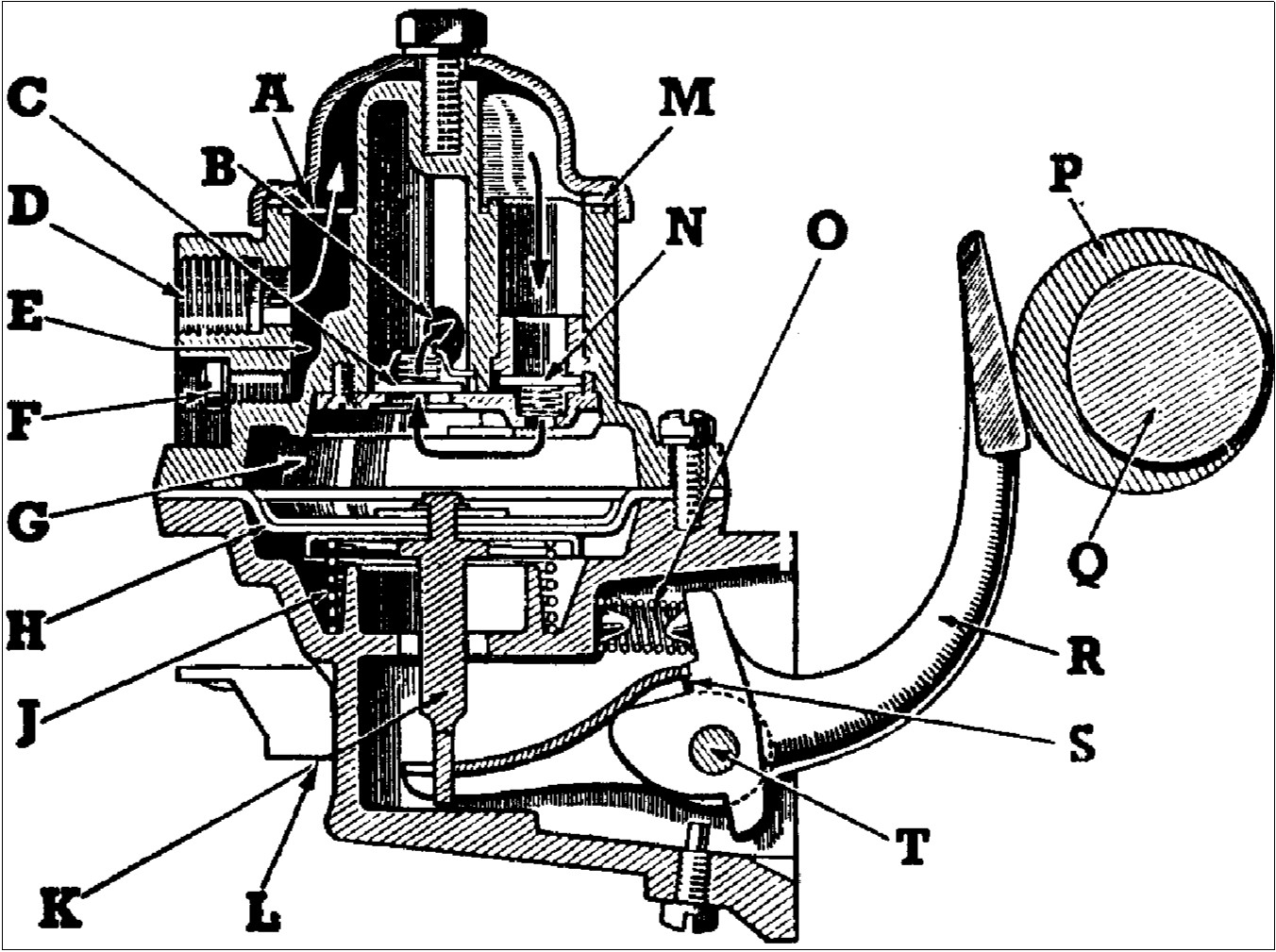

When the engine camshaft (Q) revolves, the eccentric (P) lifts the pump rocker arm (R) pivoted at (T) which pulls the pull rod (K) together with the diaphragm (H), downward against spring pressure (3), thus creating a vacuum in the pump chamber (G).

Petrol is drawn from the tank and enters at (D) into sediment chamber (E) and through a filter gauze (A) and suction valve (M) into pump chamber (G). On the return stroke the spring pressure (3) pushes the diaphragm (H) upward, forcing the fuel from the chamber (G) through the delivery valve (C) and opening (B) into the carburetter.

When the carburetter bowl is full, the float will shut the needle valve thus preventing any flow of petrol from the pump chamber (C). This will hold diaphragm (H) downward against spring pressure (I) and it will remain in this position until the carburetter requires further petrol and the needle valve opens. The rocker arm (Q) is in two pieces, the outer one operating the inner by making contact at (R) and the movement of the eccentric (0) is absorbed by the break when fuel is not required.

Spring (N) is merely for the purpose of keeping the rocker arm (Q) in constant contact with the eccentric to eliminate noise.

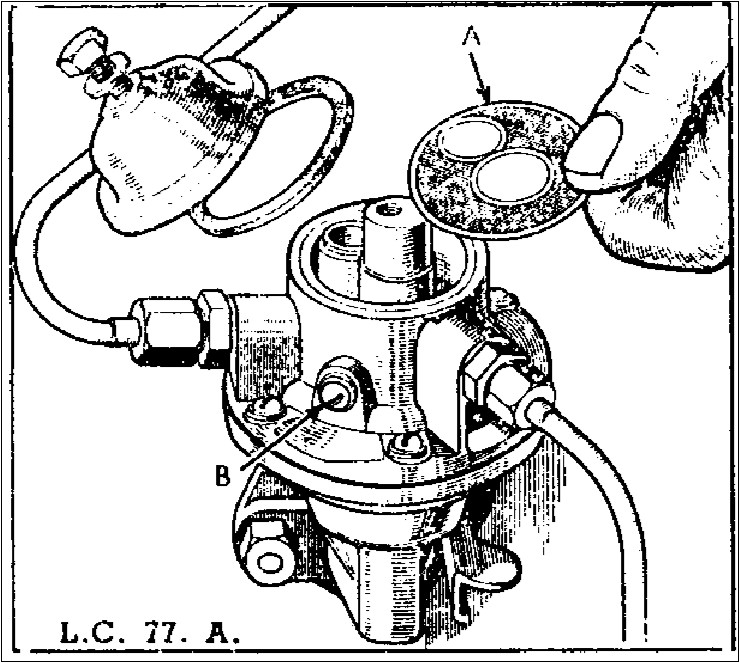

Cleaning the filter

The filter should be examined and cleaned occasionally. Access to the filter is gained by unscrewing the retaining screw and removing the dome cover, when the filter gauze itself may be lifted off its seating. Remove the drain plug and clean out the sediment chamber. Clean the filter gauze with petrol or compressed air.

The cork washer under the filter cover should be replaced if broken or if it has hardened.

When refitting the cover, make certain that the fibre washer is replaced under the head of the screw. Tighten the filter cover retaining screw just sufficiently to make a petrol-tight joint. Over-tightening will either destroy the cork washer, crack the cover or facture the main casting.